Die Piovan Gruppe entwickelt, fertigt und installiert Maschinen und schlüsselfertige Anlagen zur Maximierung der Produktivität von Blas-, Gieß- und bi-orientierten Folienextrusionsanlagen.

Die langjährige Zusammenarbeit mit den wichtigsten OEMs in der Extrusion von flexiblen Folien hat es der Gruppe ermöglicht, äußerst zuverlässige Lösungen für diesen technologisch anspruchsvollen Sektor zu entwickeln.

Die Prozesseffizienz ist unser Hauptziel um die Produktivität, auch bei häufigen Rezepturänderungen, zu maximieren und gleichzeitig Abfallprodukte sowie menschliche Fehler während der Produktion zu minimieren. Unser Fachwissen umfasst alle wichtigen Prozesse, die zu einer qualitativ hochwertigen Folienherstellung notwendig sind.

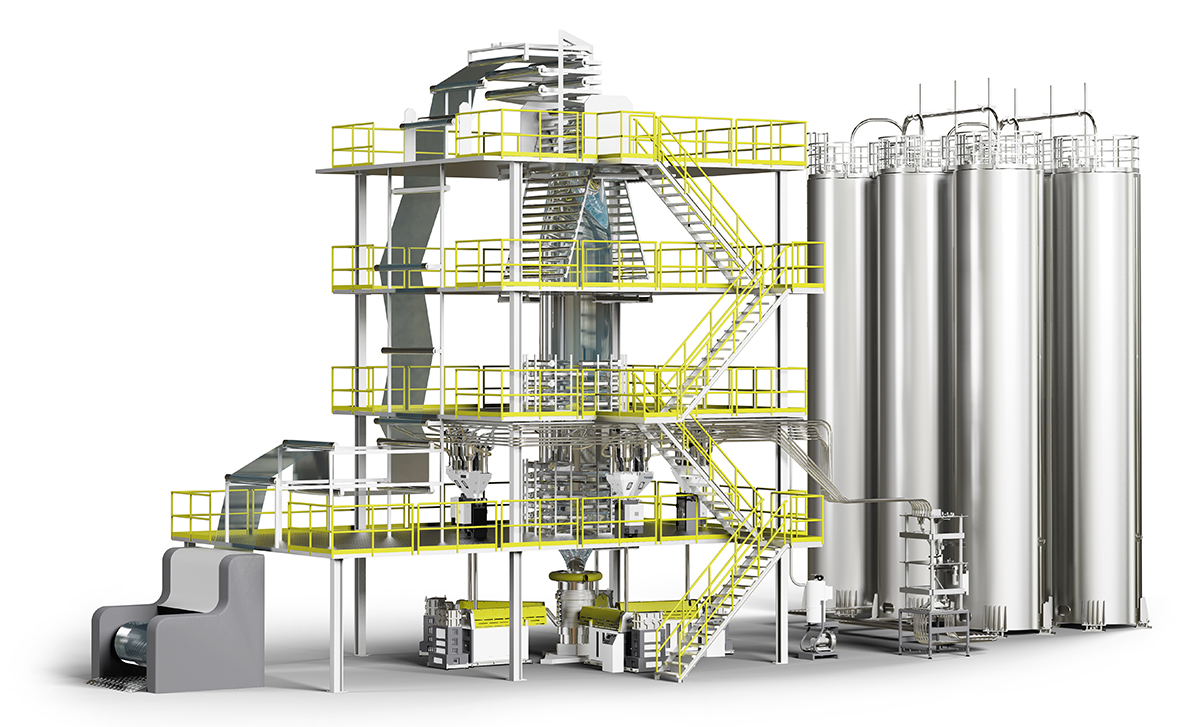

Die Piovan-Produktpalette umfasst unter anderem Lagersilos, Big Bag und Oktabin Entleerstationen, Druck-, Dichtstrom- und Vakuumförderanlagen, Entstaubungssysteme, automatische und manuelle Materialverteiler Trocknungsanlagen, gravimetrische Batch Dosiergeräte und kontinuierliche gravimetrische Dosiergeräte, Systeme zur Kontrolle der Foliendicke und -breite, manuelle und automatische Kühlringe, Steuerungen und Visualisierungssoftware.

Large diameter silos offer with great attention to functional and aesthetics for outdoor installation. Suitable for granules, flakes or powders, the Piovan silos have specific geometries and devices according to the materials to store, such as outlet air filters, extraction systems for high friction polymers, measurement solutions like load cells and protection systems for potentially explosive atmospheres. These silos are compatible with a wide range of loading methods like truck pumps, sea containers with bags, high pressure blowers for dense or semidense phase conveying systems.

Quantum E is the Piovan gravimetric batch blender for dosing and controlling the extrusion process. Its control is by means of latest-generation PLC, with colour touch screens up to 15”, for total extrusion control in real-time. Quantum E is very versatile thanks to 8 dosing stations and has been designed for total process traceability especially in conjunction with Winfactory 4.0. The particular design of the patented spherical mixer, with double load cells, assure homogeneous and precise blend of the various ingredients.

Easylink+ is the Piovan automatic coupling station able to manage up to 60 inlets/outlets with pipe size from 40 to 76 mm with minimum footprint. Designed for easy maintenance, it is totally safe for the operators both during regular functioning and service activities. The geometries, the advanced cleaning systems and the wear resistant materials assure the constant production quality in most demanding conditions. Easylink+ is available with supporting frame for floor or mezzanine installation.

The F series vacuum units are characterised by low noise level, up to 75 dB(A), and compact footprint. The F series vacuum units are available in two versions (side channels or claw pump): this allows always the best technical solution for the specific need. Such design makes them suitable for standalone installation beside the IMM and centralized feeding systems or to feed systems with medium to high pressure losses and high kg/h throughput.