Schlüsselfertige Systeme zur Handhabung von Schokolade

Customisation and attention to detail for the highest product quality

Bei der Verarbeitung und Veredelung von Schokolade, von der Kakaobohne bis zur flüssigen Schokolade, ist es von entscheidender Bedeutung, die organoleptischen Eigenschaften des Rohmaterials zu erhalten, um die höchste Qualität der Endprodukte, einschließlich Pralinen, Schokoladentafeln, Kuchen, Keksen, Schokoladeneiern und Riegeln, zu gewährleisten.

Genauer gesagt sind Präzision und Sorgfalt bei der Lagerung und dem Transport von Schokolade unerlässlich, um ihre organoleptischen Eigenschaften nicht zu verändern.

Schokoladenlager- und Transportsysteme

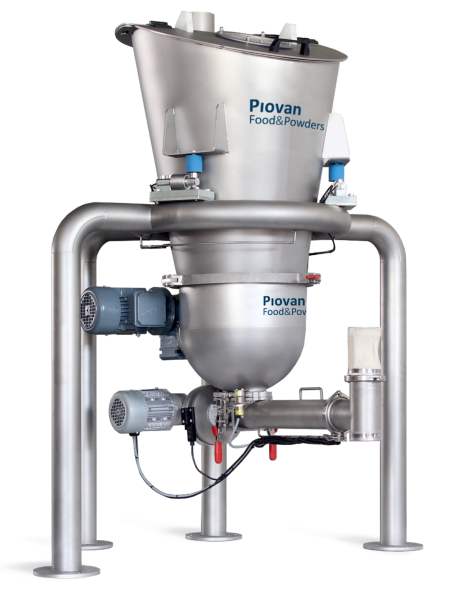

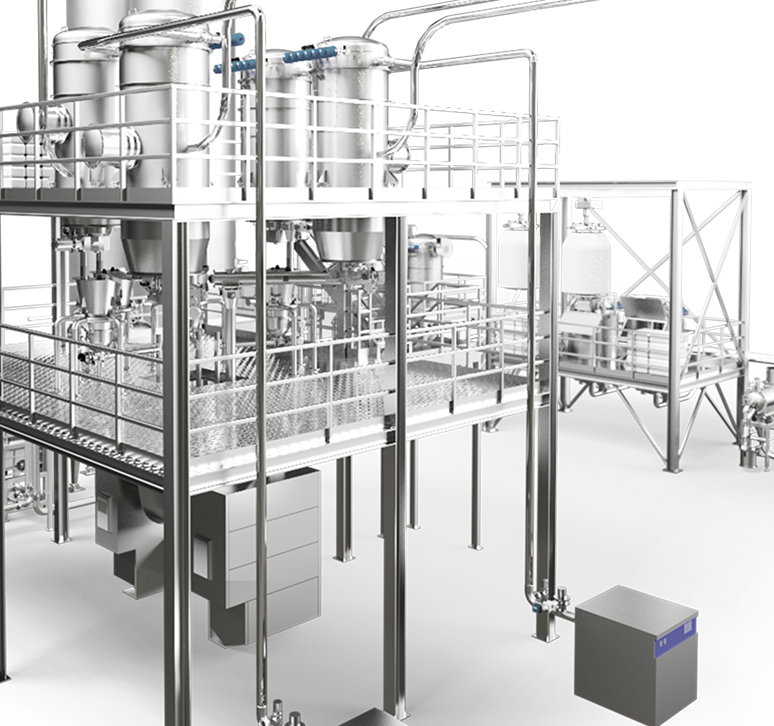

Die Piovan Gruppe bietet spezifische und maßgeschneiderte Lösungen für die Lagerung und den Transport von Schokolade, die ein Höchstmaß an Detailgenauigkeit garantieren. Insbesondere die Geometrie und das sorgfältige Finish der Innenflächen der Silos, mit internen Rührwerken, Pumpen und Wiegezellen, sorgen für einen leichten Schokoladenfluss. Darüber hinaus garantieren Transportlösungen mit doppelter Ummantelung die Aufrechterhaltung der korrekten Viskosität und maximale Sicherheit während des Transports der Lebensmittelzutaten. Die Piovan Gruppe entwirft und fertigt auch Maschinen für die Zugabe von Zusatzstoffen und Einschlüssen, die der Schokolade auf kontrollierte und präzise Weise zugefügt werden.

Die fundierte Erfahrung der Gruppe im Süßwarensektor in Verbindung mit einem präzisen technischen Kundendienst gewährleistet eine ständige Kundennähe auf globaler Ebene. Alle Maschinen der Piovan Gruppe für die Schokoladenverarbeitung zeichnen sich außerdem durch einfache Zugangsmöglichkeiten und Wartung aus und garantieren ein Höchstmaß an Sicherheit.

Unsere Ausrüstung für die Schokoladenherstellung

Lagern, Transport, Dosieren, Luft- und Prozesswasseraufbereitung, Mischen und Sieben sind nur einige der Phasen der Verarbeitung von Lebensmittelzutaten, in denen Penta und Fea, die auf Automatisierungssysteme für die Verarbeitung von Lebensmittelzutaten spezialisierten Unternehmen der Piovan-Gruppe, tätig werden können. Dank des Einsatzes von Spitzentechnologien und der ständigen Ausrichtung auf Innovation strebt die Piovan Gruppe danach, eine Marktreferenz für Lösungen mit hohem Mehrwert zu sein.

Flour cooling

Electrostatic coating

Electrostatic coating

LAGERUNG

LAGERUNG

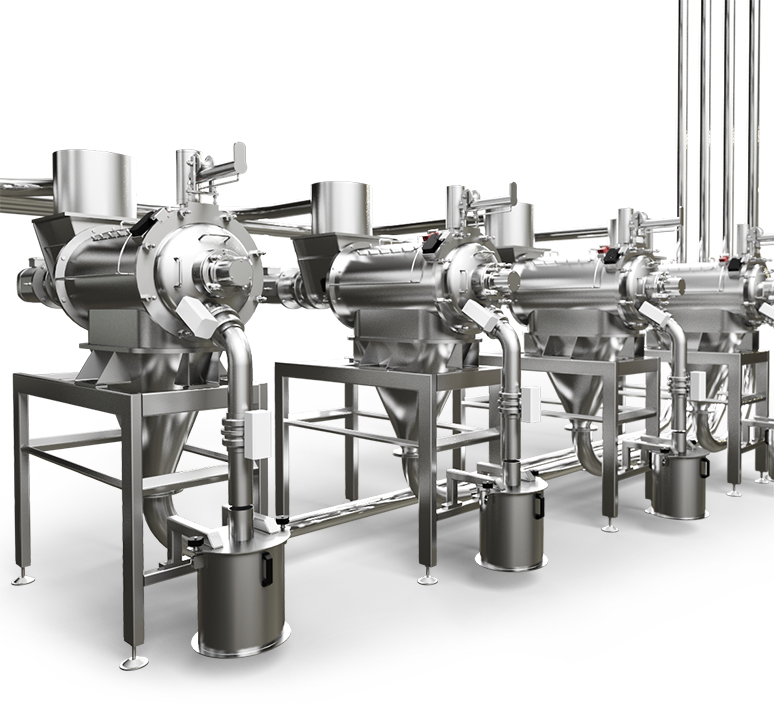

Sieving

Sieving

Dosierung

Dosierung

Supervision and Process Control

Supervision and Process Control

Dehumidification

Dehumidification

Transport

Transport

Mixing

Sugar handling

Sugar handling

More in detail, it designs and manufactures machinery for ambient air drying, conveying, shredding, storage and dosing.