Wafers & Snacks production systems

Proven experience in formulating different batter recipes

The repeatability of the characteristics of the wafer and snack batter throughout the year and in different geographical areas is of fundamental importance. Slight variations in the composition of the flours or differences in the temperature of the external environment could, however, compromise the finished product. Moreover, the frequent changes of recipe with different ingredients, depending on the type of batter to be produced, increase the cleaning operations necessary on the machinery.

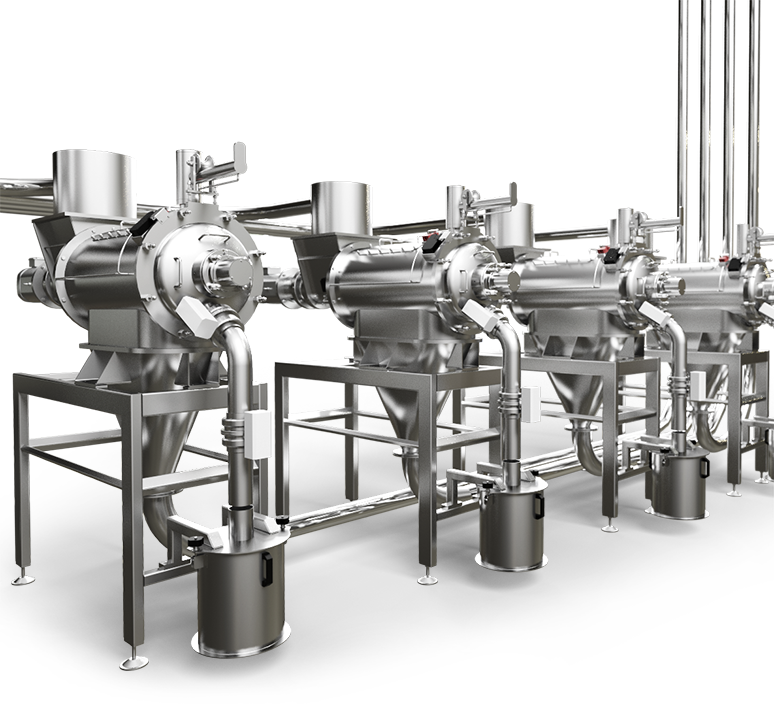

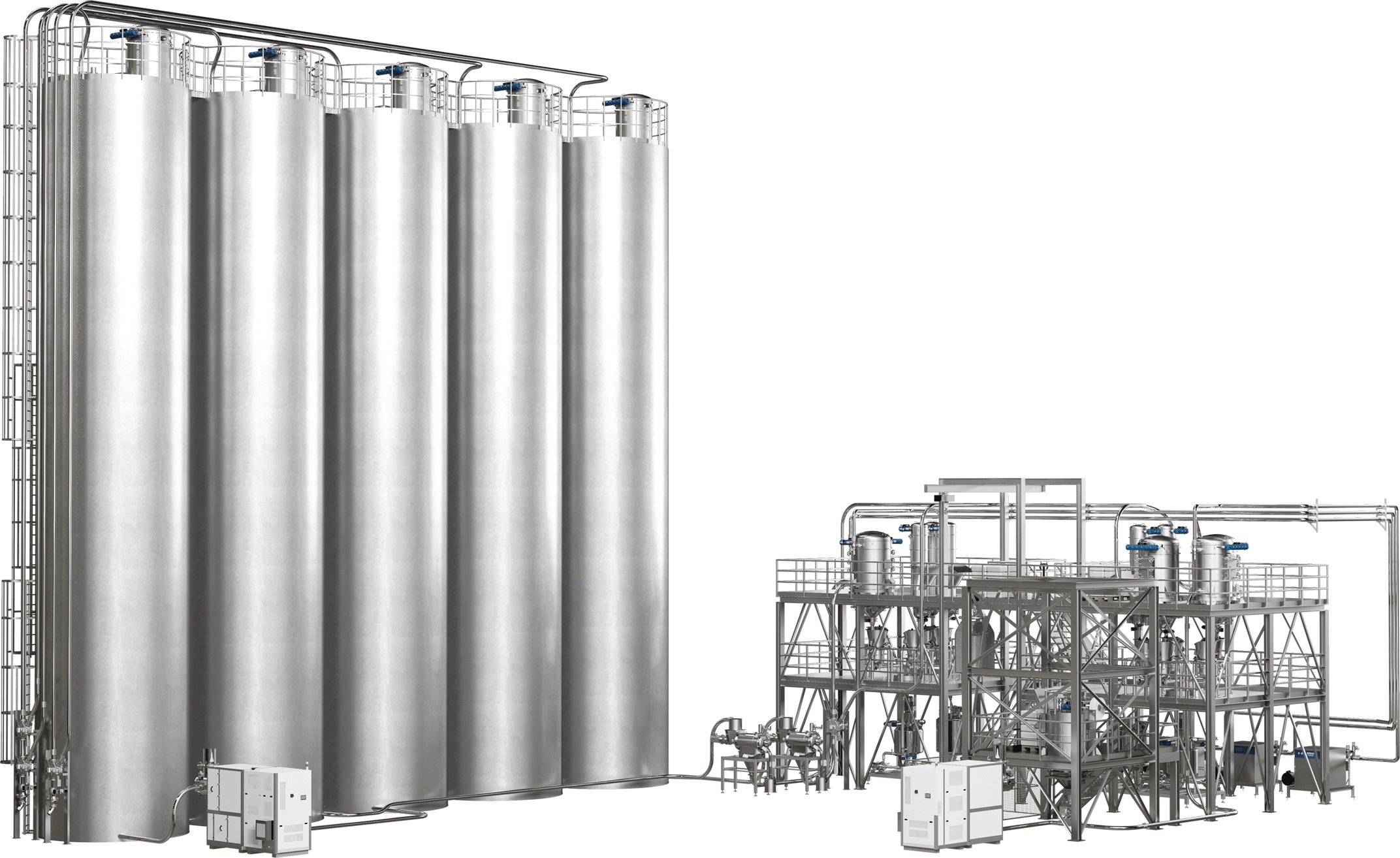

Equipment for the processing of wafers and snacks

The Piovan Group offers solutions that guarantee the repeatability of the characteristics of the final product all year round through maximum accuracy and flexibility. The plants, in fact, can be realised with gravimetric loss-in-weight dosing, where each dosing unit is dedicated to a single ingredient. This technology allows precise dosing in any working condition.

Adding the ingredients individually, in the correct order and in a controlled manner to the liquid mixture being formed guarantees the maximum quality of the final product. Piovan also offers the possibility of pre-mixing the ingredients before dissolving them in the dough.

A correct dosing process greatly reduces the need to clean production line machinery. The Group's dosing units are however designed to be extremely easy to clean without the need for dedicated technical assistance.

In-depth knowledge of all processes and consolidated experience, combined with a widespread technical assistance service, allow the Piovan Group to guarantee constant proximity to the customer at a global level.

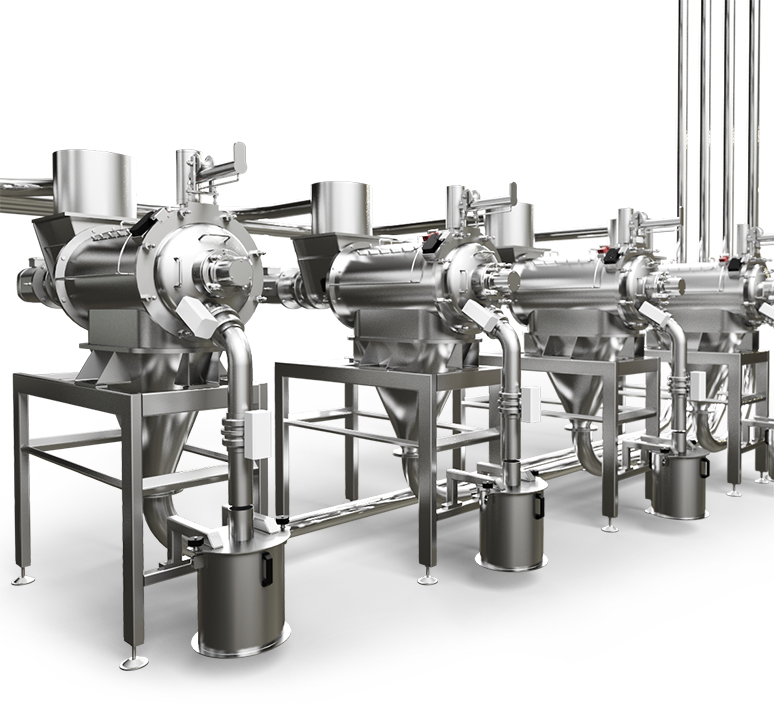

Transport

The PiovanGroup industrial conveying systems are specifically designed and manufactured for the handling of food powders and viscous liquids, including flour, sugar, cocoa, honey, starch and inclusions. Specifically, the Group's conveying systems also allow ingredients to be pre-mixed during their handling. PiovanGroup proposes dense and dilute phase pneumatic conveying systems.

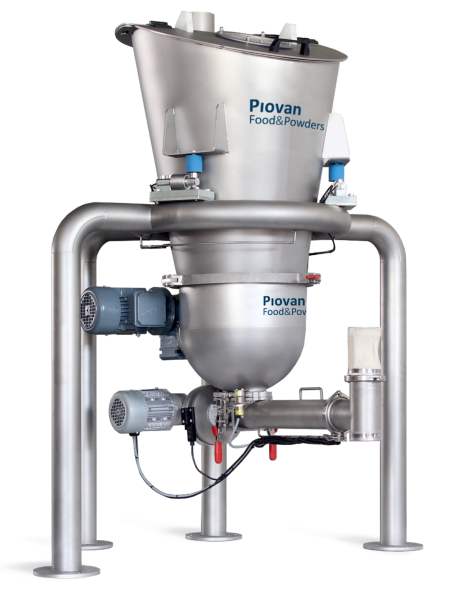

Drying Spheriko

Spheriko is the innovative dosing unit that has been specifically developed and manufactured to satisfy the requirements of the food industry. Suitable for handling food powders and additives, this weighing system features quick and simplified connections that make it extremely easy to clean, thus eliminating the need for advanced technical skills.

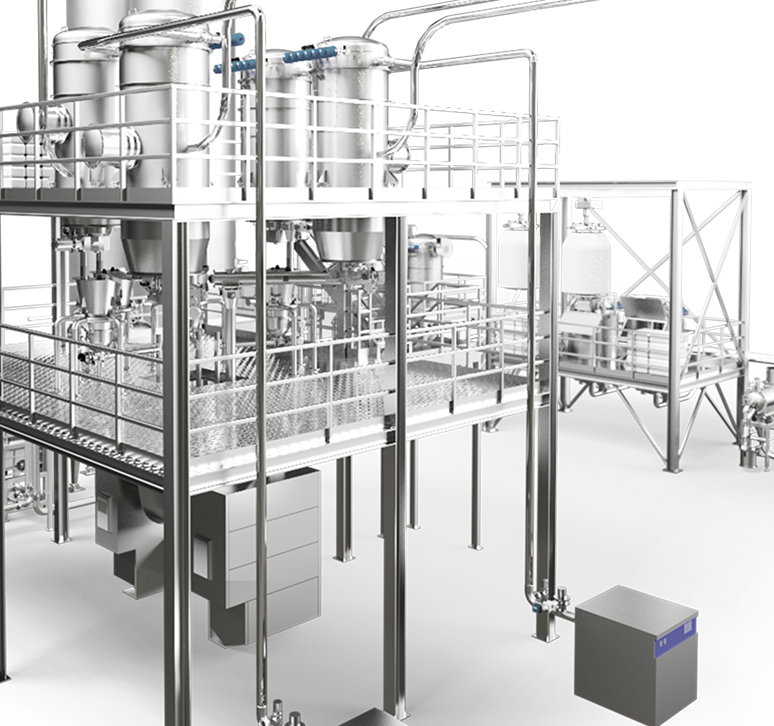

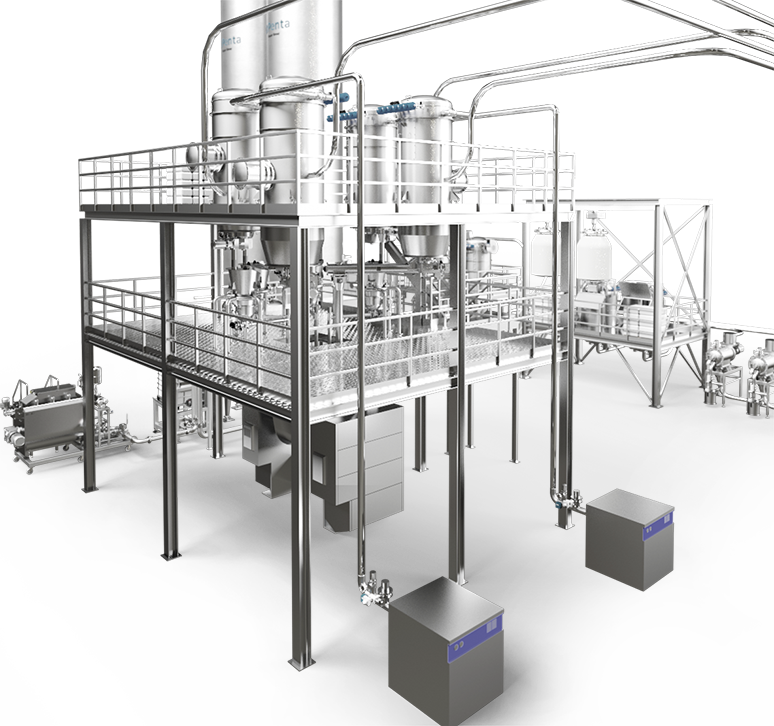

Mixing

The PiovanGroup designs and manufactures specific preparers for the production of products such as creams and caramel, suitable for powders, liquids and fats. Specifically, PiovanGroup offers the possibility to have a highly customised preparer designed according to the needs of the customer and the product to be made. The Piovan preparators can also be fed with a premix of powders ready to be used in the recipe.