Systèmes clé en main pour la gestion du chocolat

Customisation and attention to detail for the highest product quality

Lors du processus de traitement et transformation du chocolat, de la fève de cacao au chocolat liquide, il est fondamental de préserver les caractéristiques organoleptiques de la matière première, afin de garantir le maximum de qualité du produit fini, représenté par les pralinés, les barres, les gâteaux, les biscuits, les œufs et les tablettes.

Plus en détail, la précision et l’attention durant les phases de stockage et de transport du chocolat sont essentielles pour empêcher l’altération des propriétés organoleptiques.

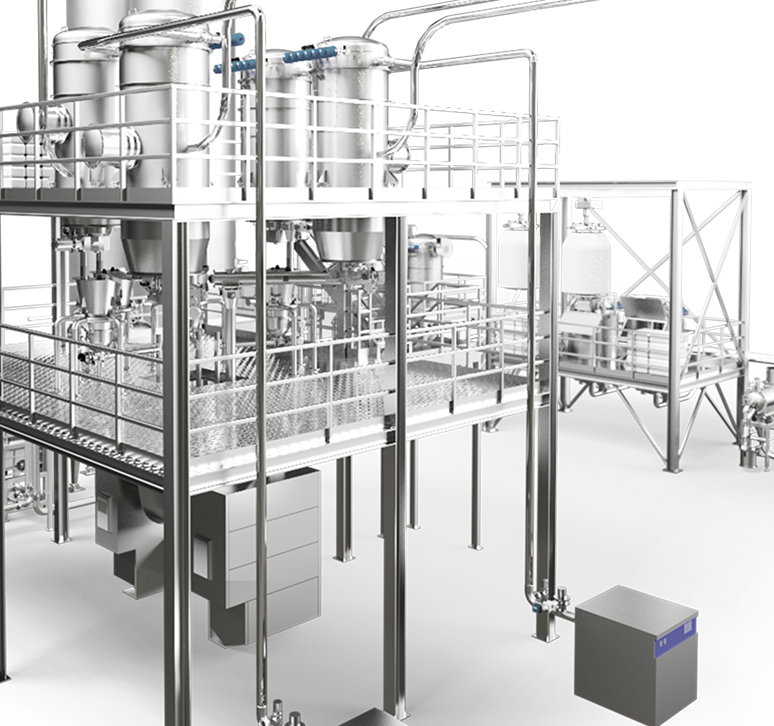

Systèmes de stockage et de transport du chocolat

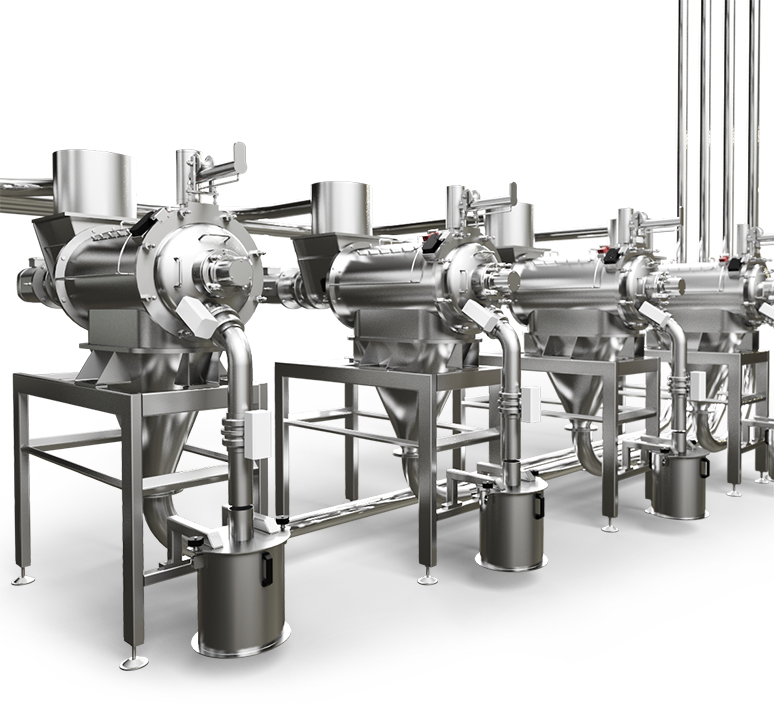

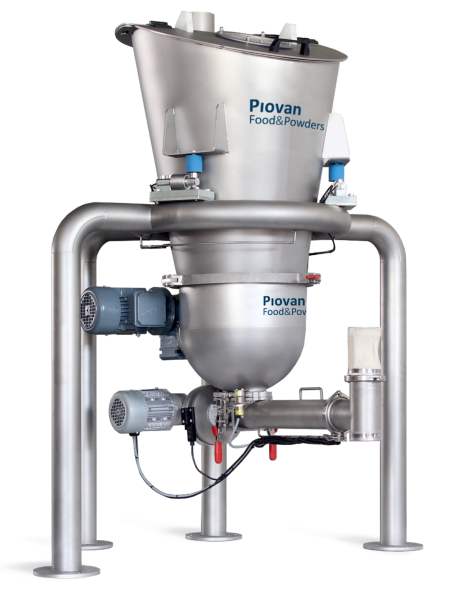

Le Groupe Piovan fournit des solutions spécifiques et extrêmement personnalisées pour le stockage et le transport du chocolat , en prêtant le maximum d’attention aux détails. Plus spécifiquement, la géométrie et la précision de la finition de la surface interne des silos, équipés d’agitateurs internes, de pompes et de cellules de charge, assurent l’écoulement facile du chocolat. De plus, les solutions de transport à double chemise garantissent le maintien de la viscosité correcte et le maximum de la sécurité lors du transport de l’ingrédient alimentaire. Le Groupe Piovan conçoit et réalise également des machines pour l’ajout d’additifs et d’inclusions, à ajouter au chocolat de manière contrôlée et précise.

La solide expérience que le Groupe a acquise dans le secteur de la confiserie, couplée avec un service d'assistance technique bien diffusé, garantit une disponibilité constante pour le client, au niveau mondial. Toutes les machines du Groupe Piovan pour le traitement du chocolat se distinguent également par leur simplicité d’accès et d’entretien et par leurs niveaux de sécurité maximum.

ÉLEVÉE

Nos équipements pour la fabrication du chocolat

Stockage, transport, dosage, traitement de l’air et de l’eau de processus, mélange et tamisage, ce ne sont que quelques unes des phases du traitement des ingrédients alimentaires pour lesquelles Penta et Fea, les sociétés du Groupe Piovan, spécialisées en systèmes d’automatisation pour la transformation des ingrédients alimentaires, sont en mesure d’intervenir. Grâce à l’emploi de technologies de pointe et à l’innovation constante, le Groupe Piovan est un point de repère du marché pour les solutions à haute valeur ajoutée.