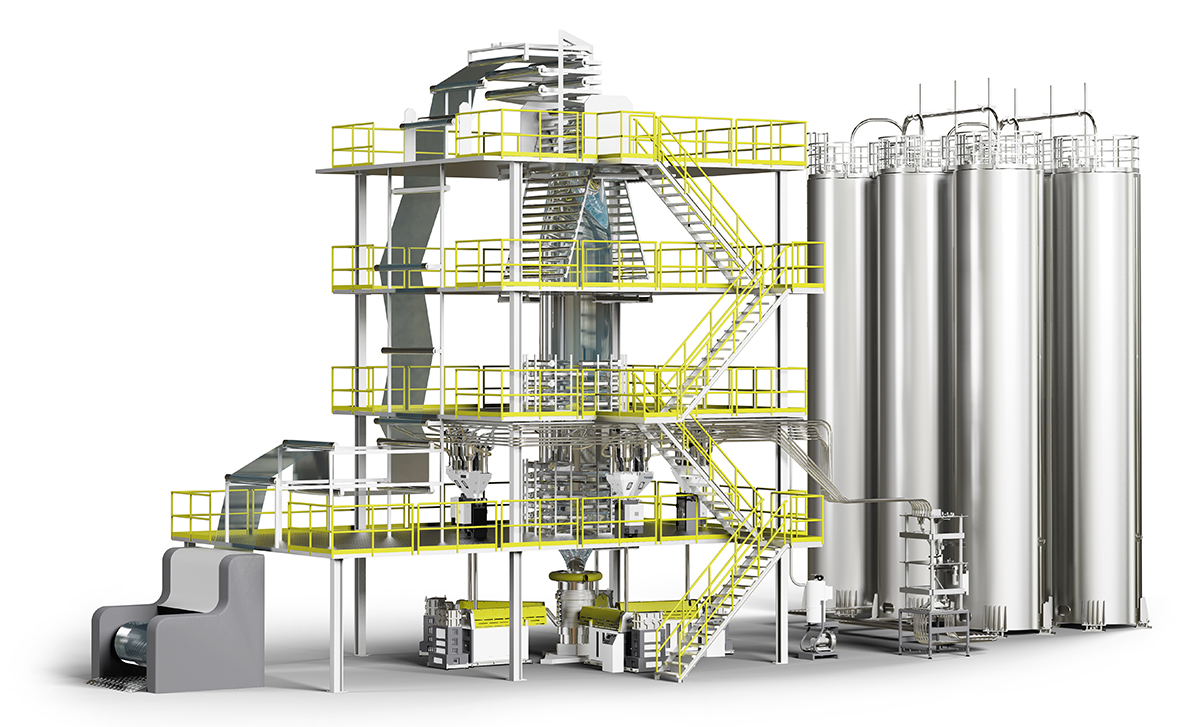

Il Gruppo Piovan progetta, realizza e installa macchinari e impianti completi chiavi-in-mano per massimizzare la produttività delle linee di estrusione di film blow, cast e biorientato.

La lunga collaborazione con i principali OEM nell'estrusione di film flessibile, ha permesso al Gruppo Piovan di sviluppare soluzioni estremamente affidabili e adatte a questo settore altamente tecnologico.

L'efficienza del processo è il nostro obiettivo principale per massimizzare la produttività, anche con frequenti cambi di ricetta, minimizzando la possibilità di errori umani e riducendo gli sprechi. La nostra esperienza riguarda tutti i processi più rilevanti che contribuiscono alla produzione di film di alta qualità.

La gamma di prodotti del Gruppo Piovan comprende, tra i vari, silos e siletti di stoccaggio, unità svuota big bag e octabin, sistemi di trasporto in vuoto e in fase densa, depolveratori, sistemi di distribuzione automatica e manuale, dryer, dosatori gravimetrici a batch e in continuo, controllo del peso e dello spessore del film, anello di raffreddamento ad aria manuale e automatico, controllo di processo e software di supervisione.

Large diameter silos offer with great attention to functional and aesthetics for outdoor installation. Suitable for granules, flakes or powders, the Piovan silos have specific geometries and devices according to the materials to store, such as outlet air filters, extraction systems for high friction polymers, measurement solutions like load cells and protection systems for potentially explosive atmospheres. These silos are compatible with a wide range of loading methods like truck pumps, sea containers with bags, high pressure blowers for dense or semidense phase conveying systems.

Quantum E is the Piovan gravimetric batch blender for dosing and controlling the extrusion process. Its control is by means of latest-generation PLC, with colour touch screens up to 15”, for total extrusion control in real-time. Quantum E is very versatile thanks to 8 dosing stations and has been designed for total process traceability especially in conjunction with Winfactory 4.0. The particular design of the patented spherical mixer, with double load cells, assure homogeneous and precise blend of the various ingredients.

Easylink+ is the Piovan automatic coupling station able to manage up to 60 inlets/outlets with pipe size from 40 to 76 mm with minimum footprint. Designed for easy maintenance, it is totally safe for the operators both during regular functioning and service activities. The geometries, the advanced cleaning systems and the wear resistant materials assure the constant production quality in most demanding conditions. Easylink+ is available with supporting frame for floor or mezzanine installation.

The F series vacuum units are characterised by low noise level, up to 75 dB(A), and compact footprint. The F series vacuum units are available in two versions (side channels or claw pump): this allows always the best technical solution for the specific need. Such design makes them suitable for standalone installation beside the IMM and centralized feeding systems or to feed systems with medium to high pressure losses and high kg/h throughput.