PiovanGroup design, manufacture and install machinery and complete turn-key plants to maximise the productivity of blown, cast and bi-oriented film extrusion lines.

The long co-operation with the main leading OEMs in the Extrusion of Flexible Film has allowed the Group to develop extremely reliable solutions suitable for this high technological demanding sector.

The process efficiency is our main target to maximise productivity, even with frequent recipe changes, whilst minimising the possibility of human error and reducing waste. Our expertise involves all the most relevant processes that contribute to high quality film manufacturing.

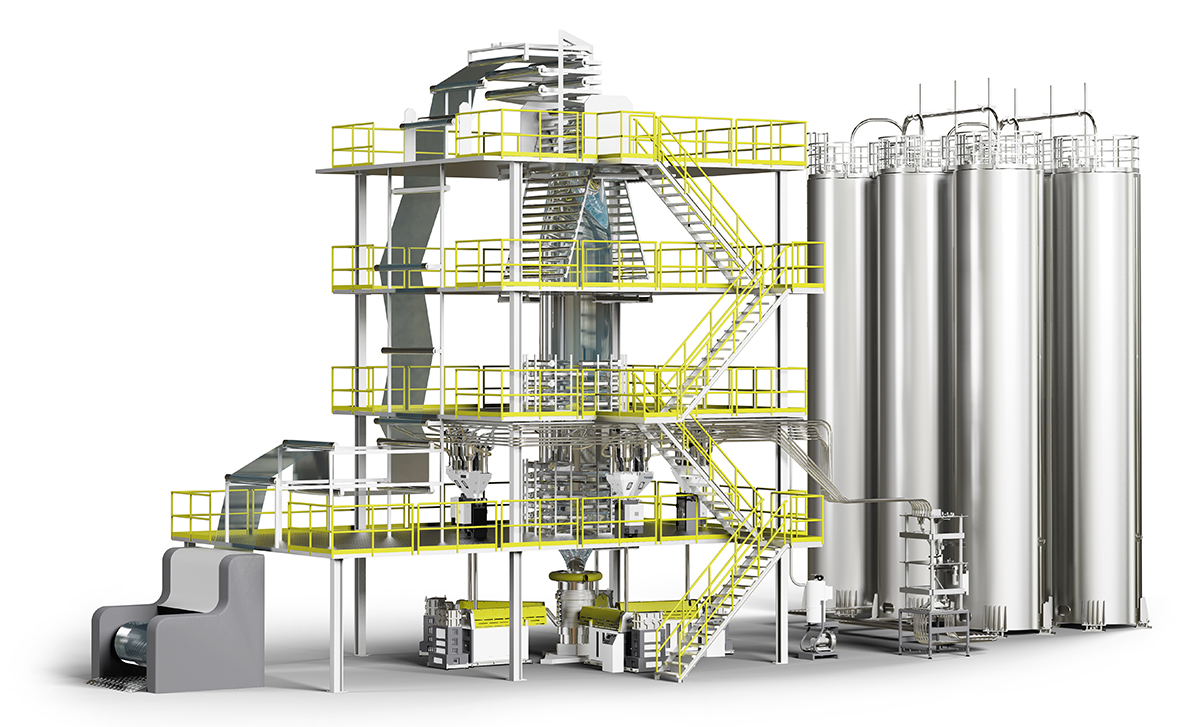

Piovan's range of products includes, among others, storage silos, daily bins, big bag and octabin unloading units, pressure, dense phase and vacuum pneumatic feeding systems, de-dusting units, automatic and manual distribution systems, dryers, gravimetric batch and gravimetric continuous blenders, film weight and thickness control, manual and automatic air cooling ring, process control and supervising software.

Large diameter silos offer with great attention to functional and aesthetics for outdoor installation. Suitable for granules, flakes or powders, the Piovan silos have specific geometries and devices according to the materials to store, such as outlet air filters, extraction systems for high friction polymers, measurement solutions like load cells and protection systems for potentially explosive atmospheres. These silos are compatible with a wide range of loading methods like truck pumps, sea containers with bags, high pressure blowers for dense or semidense phase conveying systems.

Quantum E is the Piovan gravimetric batch blender for dosing and controlling the extrusion process. Its control is by means of latest-generation PLC, with colour touch screens up to 15”, for total extrusion control in real-time. Quantum E is very versatile thanks to 8 dosing stations and has been designed for total process traceability especially in conjunction with Winfactory 4.0. The particular design of the patented spherical mixer, with double load cells, assure homogeneous and precise blend of the various ingredients.

Easylink+ is the Piovan automatic coupling station able to manage up to 60 inlets/outlets with pipe size from 40 to 76 mm with minimum footprint. Designed for easy maintenance, it is totally safe for the operators both during regular functioning and service activities. The geometries, the advanced cleaning systems and the wear resistant materials assure the constant production quality in most demanding conditions. Easylink+ is available with supporting frame for floor or mezzanine installation.

The F series vacuum units are characterised by low noise level, up to 75 dB(A), and compact footprint. The F series vacuum units are available in two versions (side channels or claw pump): this allows always the best technical solution for the specific need. Such design makes them suitable for standalone installation beside the IMM and centralized feeding systems or to feed systems with medium to high pressure losses and high kg/h throughput.