CR

From 150 to 4,000 dm3

- Suitable for granules, flakes and regrind materials

- Robust and reliable

- Homogeneous agitation of the material

CR assures best crystallisation, improving the drying phase. The design has been specifically developed to exceed the material glass transition temperature and to guarantee homogeneous crystallization, assuring optimal flow of the material.

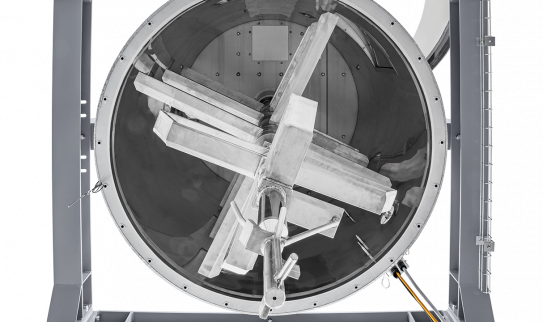

Crystallising hoppers are equipped with high efficiency planetary motor gears to guarantee low rotation speed of the vertical paddle shaft and minimize dust creation.

The vertical shaft is assembled with screw connections between the different paddle groups, in order to facilitate maintenance and the substitution of each single paddle.

The process is kept under control with a complete set of temperature probes and level sensors.

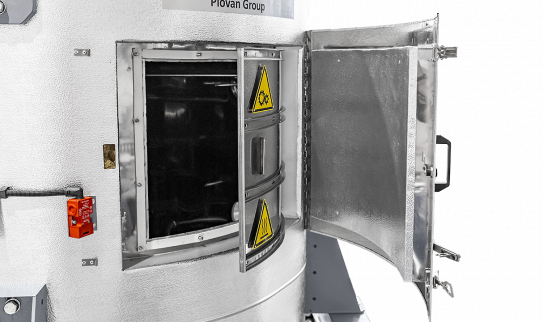

The access to the inner part is facilitated by a large hinged and insulated door and by the removable cone (configuration according to size).

CR crystalliser can run both with flakes and granules.