选择你所在的国家或地区,查看当地内容。

产品安全的质量和可追溯性

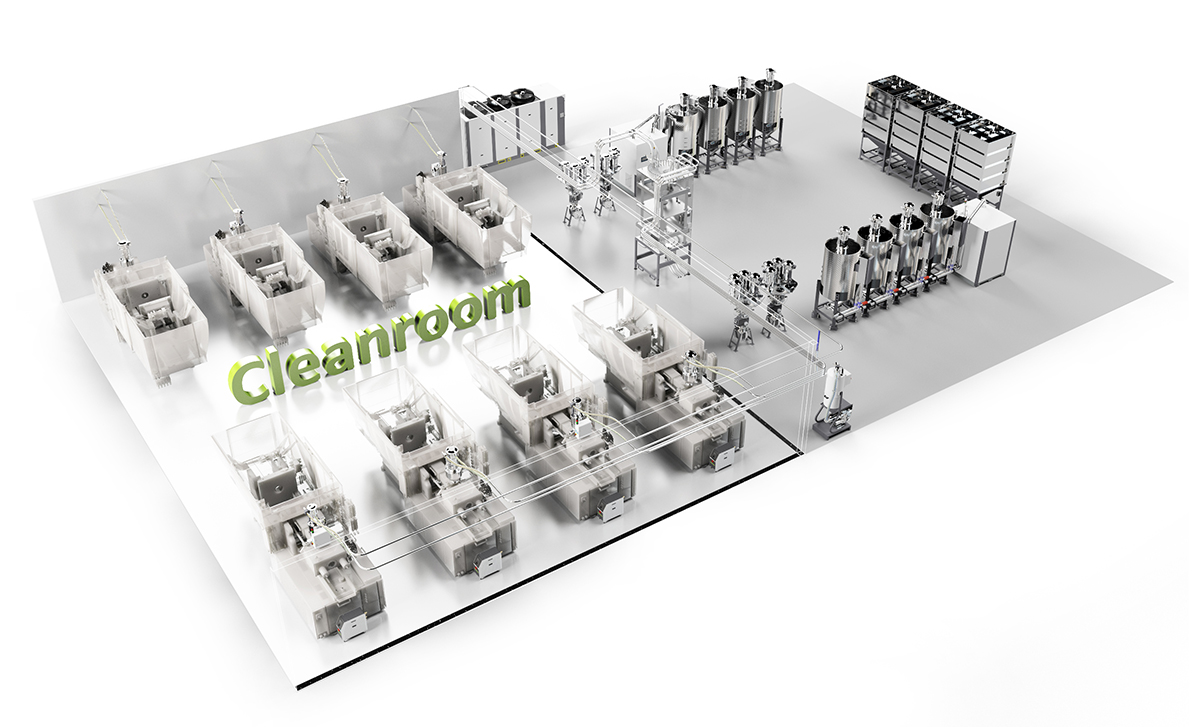

Plastics are essential for medical devices and pharmaceutical packaging. Traceability, cleanliness, safety and precision are essential. Minimising the risk of contamination and maximising the quality of finished products, such as syringes, blister packs, cannulae, blood bags and pipes, fittings and cleanrooms, is therefore crucial in any type of production process: injection molding or high-precision blow molding.

GMP is a single or multi hopper drying system, that can adapt and automatically control operating parameters, such as temperature, dew point and flow rate of the process air, according to the production detected. The GMP range is available in 3 configurations: SMART, PLUS and ADAPTIVE. In case of many different raw materials to dry, one GMP dryer can be combined with a multi-hopper system.

The F series vacuum units are characterised by low noise level, up to 75 dB(A), and compact footprint. The F series vacuum units are available in two versions (side channels or claw pump): this allows always the best technical solution for the specific need. Such design makes them suitable for standalone installation beside the IMM and centralized feeding systems or to feed systems with medium to high pressure losses and high kg/h throughput.

Easylink+ is the Piovan automatic coupling station able to manage up to 60 inlets/outlets with pipe size from 40 to 76 mm with minimum footprint. Designed for easy maintenance, it is totally safe for the operators both during regular functioning and service activities. The geometries, the advanced cleaning systems and the wear resistant materials assure the constant production quality in most demanding conditions. Easylink+ is available with supporting frame for floor or mezzanine installation.

Quantum are gravimetric blenders suitable for all plastic materials, immune to vibrations and easy to use. All the surfaces that come into contact with the process material are stainless steel and can be used in the most critical environments, like the medical and food packaging sectors. Its semispherical shape assures perfect mixing without stagnation. The range can have up to 6 dosing stations, which can be easily removed, for emptying or cleaning. The mixer, which can be installed remotely over the processing machine, assures the best mixing, especially after conveying of materials with different densities over long distances.

Ryng is the best solution for real time production monitoring and the usage of raw material. It integrates a high precision load-cell that measures the weight of material loaded into the receiver. The system precision is 1% in typical installation sites with vibration. All the throughput information are recorded also in Winfactory 4.0, to make possible advance analysis of consumptions and material batch tracking.

Easytherm EP is the new mould temperature control unit characterized by user-friendliness, flexibility and reliability, for injection, blow moulding and extrusion processes. Easytherm EP operates at temperatures up to 180 °C. A new interior and exterior layout, redesigned ergonomic control, coupled with high-end components, characterise a versatile machine that guarantees reliability and long term performances. Easytherm EP is already set up for use in Industry 4.0 environments with a wide range of communication protocols, including OPC-UA platform and is Winfactory 4.0 ready.

DPA Series use compressed air for drying hygroscopic polymers. The running parameters can be easily loaded from the internal database. Thanks to the Material Database, the control automatically regulates the process condition once the material has been selected and the hourly throughput has been set. With the use of desiccant cartridges DPA can reach lower Dew Point values (up to –40°C).

Easycool+ is the air cooled compact chiller that has been conceived, designed and built for cooling in specific industrial processes for plastics.

Flexibility, energy efficiency, reduced footprint and low environmental impact: Easycool+ adds value and reduces the costs associated with the investment.

When processing plastics, the temperature ranges to be maintained for different processes can vary significantly, requiring that the chiller provides different conditions of pressure and flow rate: the flexibility of Easycool+ ensures the best operating conditions are maintained at all times. The optimum temperature ensures the best product quality.

Easytherm EW is the new mould temperature control unit that uses water as process fluid with an open system configuration, for injection, blow moulding and extrusion processes. Easytherm EW operates at temperatures up to 90 °C. A new interior and exterior layout, redesigned ergonomic control, coupled with high-end components, characterise a versatile machine that guarantees reliability and long term performances. Easytherm EW is already set up for use in Industry 4.0 environments with a wide range of communication protocols, including OPC-UA platform and is Winfactory 4.0 ready.

The PTUN drying hoppers can be combined in a multi-hopper drying system in order to guarantee maximum flexibility. Each hopper is equipped with an electrical heater on board. The control allows the setting of a different temperature for each hopper; in this way different materials can be dried at the same time, using the right process parameters for each of them. The process air flow passing through the hopper can be adjusted by the operator or in a fully automatic mode according to the actual production with Modula.

特色产品

Flexcool 解决方案可以使用环境温度来冷却加工过程中的设备。 这种独特的战略性的特点使 Flexcool 理想地适用于具有不同特性的注塑机,即在工作环境中不同的用户的需要在不同的加工条件(温度,流量,压力)下操作。 Flexcool 确保了最高水平的控制,灵活性和能源效率。

凭借在 PET 瓶坯生产工艺方面的特殊技能和深厚知识,我们可提供定制解决方案,满足 PET 瓶坯行业的特殊冷却需求。

产品包括冷热一体机系列,具有加热和冷却在塑料加工过程中注塑机和吹塑机的处理电路的功能。采用单电路或双电路,能够以最低的能耗提供最大的冷却量。

高效的热交换和操作的可靠性是模温机的特点。

干式冷却器提供满足各种工业过程和应用的最佳解决方案,在温度高于或等于外部环境温度的情况下,必须对热交换过程的流体进行持续地冷却。这代表了低成本和低能耗,是冷却塔的有效替代方案。

泵是让冷却水及冷冻水流通于整个回路的设备,必须受到高度关注与重视。

百旺为整个工业冷却解决方案系列开发所有软件。