选择你所在的国家或地区,查看当地内容。

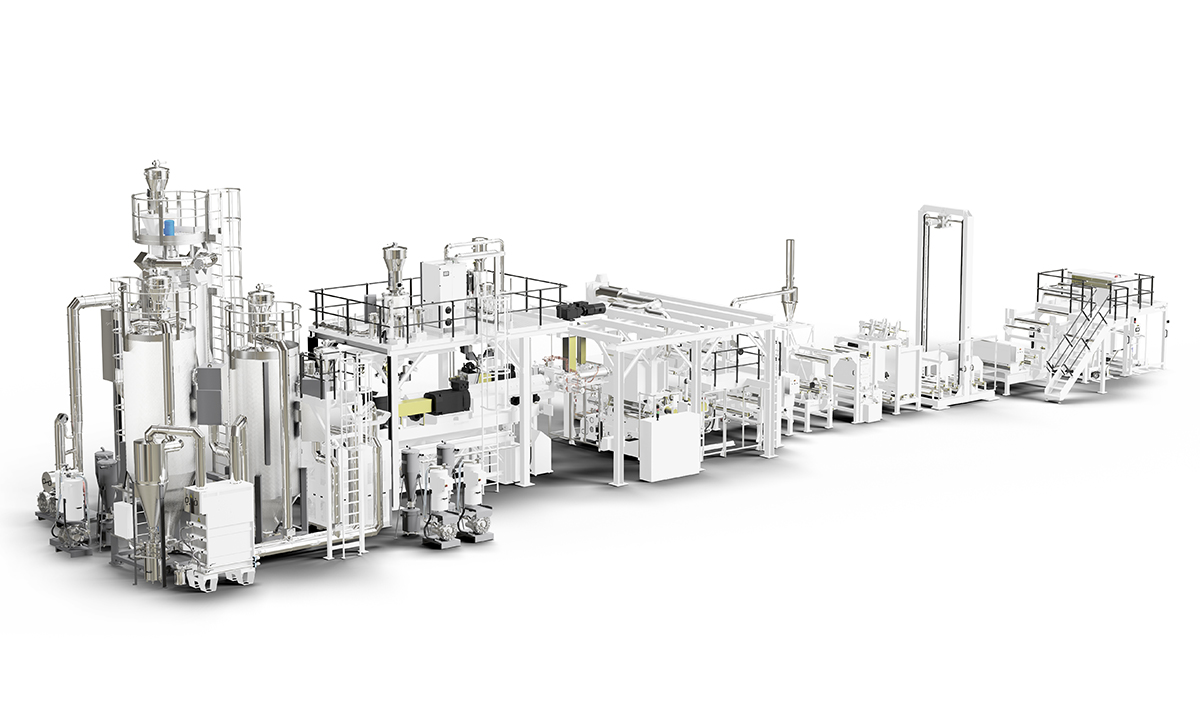

Tailored solutions suitable for all polymers for the production of technical and thermoforming sheets

These plates in different plastic polymers (ABS, PET, PS, PP, PLA), of various thicknesses, with different colours and finishes, are intended for various application sectors, including the food, beverage, automotive and household appliances industries. More in detail, the sheets are suitable for the production of various types of objects, such as trays, trays, displays, chandeliers and car interior linings.

For more than 30 years the Piovan Group has been developing automation systems for the production of technical and thermoforming sheets.

The Group designs and manufactures customised turn-key solutions suitable to prepare and use both internal regrind and post-consumer material (PCR) for the extrusion process. The technology of Piovan plants maximises the quality of the finished product and ensures that all processing is carried out to the highest quality standards.

Piovan is a partner of the major OEMs and has developed dedicated solutions for the production of technical and thermoforming sheets for more than 250 customers.

The F series vacuum units are characterised by low noise level, up to 75 dB(A), and compact footprint. The F series vacuum units are available in two versions (side channels or claw pump): this allows always the best technical solution for the specific need. Such design makes them suitable for standalone installation beside the IMM and centralized feeding systems or to feed systems with medium to high pressure losses and high kg/h throughput.

Suitable for high throughput, the CS Series vacuum receivers are specifically designed for material prone to bridging. Flake is particularly complex to handle due to its propensity to bridge. The cone angle and availability of bridge breakers ensure material discharge. Pneumatic flaps can be fitted for very light material.

The CDF condensing unit is the solution developed by Piovan for removing low-boiling contaminants from the process air, released during the drying process of post consumer products like rPET or flakes. Metallic filters remove dust particles before the condensing phase. The cooling batteries then remove the low-boiling oils which drop into collecting tank easy removable.

The T1 hoppers are specifically designed for high capacity productions. These insulated drying hoppers are characterised by optimum ratio between height and diameter for proper heat exchange. Made in stainless steel for preserving at best the processed material, T1 hoppers are easily accessible to all their parts, thanks to the inspection door.

Lybra LG is a continuous weight-loss gravimetric doser that can be easily integrated in supervision system. The dosing auger available in 3 configurations, single, dual or triple flight screws, assures high level of accuracy and repeatability. The intuitive graphical user interface allows the operator to control the main parameters such as actual and set values or instantaneous production and access all unit’s functions. The central body is provided with a static mixer that makes the additives entering in the middle of the virgin column, assuring a perfect mixing.

GMP is a single or multi hopper drying system, that can adapt and automatically control operating parameters, such as temperature, dew point and flow rate of the process air, according to the production detected. The GMP range is available in 3 configurations: SMART, PLUS and ADAPTIVE. In case of many different raw materials to dry, one GMP dryer can be combined with a multi-hopper system.

Suitable for granules, flakes and regrind materials, the CR crystalliser assures the best crystallisation, improving the drying phase. The design has been specifically developed to exceed the material glass transition temperature and to guarantee homogeneous crystallization, assuring optimal flow of the material. Crystallising hoppers are equipped with high efficiency planetary motor gears to guarantee low rotation speed of the vertical paddle shaft and minimize dust creation. The process is kept under control with a complete set of temperature probes and level sensors.

特色产品

Flexcool 解决方案可以使用环境温度来冷却加工过程中的设备。 这种独特的战略性的特点使 Flexcool 理想地适用于具有不同特性的注塑机,即在工作环境中不同的用户的需要在不同的加工条件(温度,流量,压力)下操作。 Flexcool 确保了最高水平的控制,灵活性和能源效率。

凭借在 PET 瓶坯生产工艺方面的特殊技能和深厚知识,我们可提供定制解决方案,满足 PET 瓶坯行业的特殊冷却需求。

产品包括冷热一体机系列,具有加热和冷却在塑料加工过程中注塑机和吹塑机的处理电路的功能。采用单电路或双电路,能够以最低的能耗提供最大的冷却量。

高效的热交换和操作的可靠性是模温机的特点。

干式冷却器提供满足各种工业过程和应用的最佳解决方案,在温度高于或等于外部环境温度的情况下,必须对热交换过程的流体进行持续地冷却。这代表了低成本和低能耗,是冷却塔的有效替代方案。

泵是让冷却水及冷冻水流通于整个回路的设备,必须受到高度关注与重视。

百旺为整个工业冷却解决方案系列开发所有软件。